Home >> Products >> API-ANSI Standard >> Cast Iron >> Strainer >> ANSI Cast Iron Y-Strainer

Cast Iron Y-Strainer is a device that mechanically removes unwanted solids from liquid, gas or steam lines through perforated or wire mesh filter elements. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Product Details

1. Design and Manufacture

2. Face to Face

3. Flange End: ANSI B16.1

4 Test: API-598

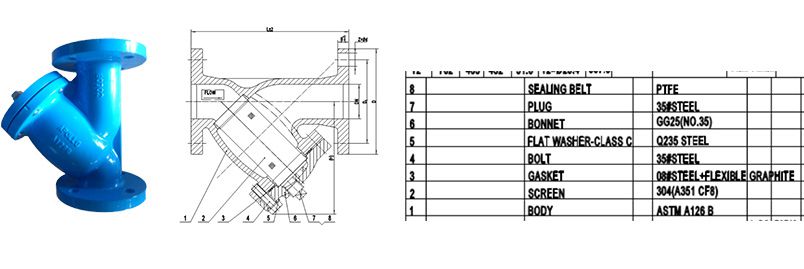

| Parts Name | Materials |

| Body、Bonnet | ASTM A126 B |

| Screen | SS304 |

| Plug | ASTM 1035 |

Y-Strainer is a very cost-effective filtration solution in many applications. In the case where the amount of material to be removed from the stream is relatively small, resulting in long intervals between screen cleaning, the filter can be manually cleaned by closing the production line and removing the filter cover.

For applications with heavier dirt loads, Cast Iron Y-Strainer can be equipped with a "blowing" connection, allowing the filter to be cleaned without removing it from the filter body.

Cast Iron Y-Strainer is used in various liquid filtration applications to protect downstream process system components in many industries, including chemical processing, petroleum, power generation, and ships. Y-filters are very common in water treatment applications that protect equipment that may be damaged or blocked by unwanted sand, gravel, or other debris.

In addition to steam, Cast Iron Y-Strainer is commonly used in air and natural gas applications. Here, high pressure is not uncommon. However, unlike steam, high air pressure does not mean high temperature, so an ordinary carbon steel body with sufficient wall thickness is usually sufficient.

These y-strainers are usually supplied in one of four materials: iron, carbon steel, bronze or stainless steel.

Cast Iron Y-Strainer is the most commonly used because it has the lowest cost and good corrosion resistance in many services.

Carbon steel y-strainers are used at higher temperatures or have thermal or mechanical shock issues, which makes them very popular in the petroleum and petrochemical industries.

Bronze y-strainer can handle thermal and mechanical shock better than Cast Iron Y-Strainer, and performs better in certain corrosive applications, but is limited in temperature range.

Stainless steel Y-Strainer is needed where corrosion may be a problem and is widely used in the chemical, food and pharmaceutical industries.