Have you checked your cast steel check valve recently? Regular maintenance is crucial for ensuring that your check valves function effectively, guaranteeing safe fluid flow and preventing costly spills or system failures. Over time, damage or wear and tear can lead to issues that compromise the efficiency of your system. But how can you ensure that your check valves remain "healthy" and function as intended? In this guide, we provide simple, yet comprehensive guidelines to maintain your check valves, improve their lifespan, and avoid costly repairs.

C

A check valve is a vital component in many fluid systems. Its primary purpose is to allow the fluid to flow in one direction and prevent backflow, which could cause contamination or damage to equipment downstream. If you need to direct fluid through a pipe, and ensure it flows only in one direction, a check valve is indispensable.

Check valves work based on a simple two-way mechanism: they open to allow flow when the pressure is above a certain threshold and automatically close when flow reverses or when downstream pressure becomes excessive. This unique mechanism prevents backflow, maintaining the integrity and performance of the system.

ㆍWater and Waste Pumping Systems

ㆍWater Supply Pipes

ㆍSewage Treatment Systems

ㆍHeating Systems

ㆍFire Hose and Protection Systems

ㆍMarine and Naval Industries

ㆍOil and Gas Pipelines

ㆍFlush Toilet Systems

There are several types of check valves used in different systems, such as rotary check valves, lift check valves, piston check valves, and ball check valves. Each type is designed to cater to specific operational conditions and media types, making it crucial to select the right valve for your system.

>> Look at all our check valves types!

Although a Gost Check Valve (a popular brand of check valves) doesn’t require excessive maintenance, periodic inspections and care are vital. Foreign matter, debris, or corrosion can obstruct the valve’s proper functioning, leading to leakage, backflow, or system inefficiencies. Here are a few key maintenance steps you can take to ensure your check valves perform at their best:

Step 1: Keep the Valve Area Clean

The simplest yet most effective maintenance tip is to keep the check valve clean. Dirt, dust, or any particles around the valve can degrade its performance. Regularly wipe down the valve and surrounding components with a soft towel to remove any debris. If the dirt accumulates, use a wire brush to clean it off. Keeping the valve area clean helps prevent unwanted buildup and potential blockages.

Step 2: Regularly Inspect the Check Valve

Performing regular checks on your check valves is critical to preventing expensive repairs or replacements. These inspections help detect potential problems early before they cause significant system downtime. When inspecting the valve, make sure to:

ㆍCheck for Leaks: Leaks are often the first sign of a valve malfunction. Small leaks can lead to severe problems if left untreated.

Inspect for Corrosion: Corrosion, rust, or mineral buildup can weaken the valve structure and cause malfunctioning. Check the valve housing and internal components for signs of corrosion.

ㆍCheck for Valve Wear or Damage: If you notice any damage or worn parts, it’s time to replace the valve. Damaged components can compromise the valve’s integrity and functionality.

ㆍTest Valve Operation: Open and close the valve manually (if possible) to ensure it operates smoothly without sticking.

ㆍMonitor Pressure and Temperature: Ensure the fluid pressure and temperature passing through the valve fall within the valve’s rated limits. Exceeding these limits can cause the valve to malfunction or close prematurely.

ㆍNote on High-Pressure Valves: If your system operates under high pressure, inspect these valves more frequently, as they are more prone to wear and damage.

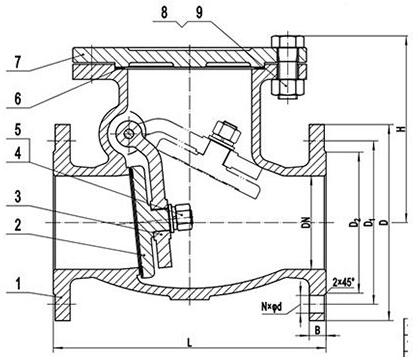

Check Valve Structure

Step 3: Remove Debris and Clean Thoroughly

Over time, debris, dirt, or other particles may accumulate inside the valve and obstruct the flow or valve mechanism. If your check valve is removable, take it out for a thorough cleaning. Here’s how you can clean it effectively:

ㆍDisassemble the Valve: Remove the valve from the piping system and check it for any debris, corrosion, or wear marks.

ㆍClean with Hydraulic Oil: Use hydraulic oil or another compatible cleaning liquid to remove debris and clean the internal surfaces. Avoid using abrasive substances that could damage the internal parts.

ㆍInspect Valve Housing: Check the housing for signs of corrosion, rough surfaces, or other forms of damage. You may need to polish rough surfaces to maintain smooth operation.

Step 4: Lubricate the Valve Mechanism

Lubrication is a critical step that is often overlooked but can significantly extend the lifespan of your check valve. Proper lubrication helps prevent wear and tear on the moving parts and ensures smooth operation. Here’s how you can properly lubricate the valve:

ㆍApply the Right Lubricant: Ensure you use the correct lubricant that matches the operating conditions and the type of system. Some systems may require specialized lubricants, so it’s essential to consult the manufacturer’s recommendations.

ㆍLubricate the Valve Chamber: Apply the lubricant to the valve chamber and make sure it flows into all moving parts. Check that the lubricant is evenly distributed.

ㆍAvoid Harmful Lubricants: Be cautious about using lubricants that contain clay or other solid thickeners. These materials can solidify over time, leaving residues that impair valve operation.

Step 5: Use Protective Insulation

Extreme temperatures can significantly affect the performance of check valves. If your piping system operates in outdoor or extreme environments, consider adding insulation to protect the check valve from temperature fluctuations. Proper insulation helps to prevent temperature-related damage and ensures the valve operates within its optimal range.

Regular maintenance of check valves isn’t just about avoiding failures; it’s about ensuring the long-term reliability and efficiency of your fluid system. Properly maintained check valves help:

ㆍExtend Equipment Lifespan: Regular maintenance prevents premature wear and helps components last longer.

ㆍImprove System Efficiency: A well-maintained valve will work as designed, improving the overall performance of the system.

ㆍReduce Repair Costs: Detecting and addressing issues early can save significant repair costs in the future.

ㆍEnsure Safety: Check valves that are regularly maintained reduce the risk of backflow, contamination, or pressure-related accidents.

According to recent industry data, check valve failures account for a significant portion of mechanical breakdowns in fluid systems. In industries such as oil and gas, water treatment, and wastewater management, these failures can lead to costly downtime and environmental hazards. Regular inspection and maintenance can reduce the incidence of check valve failure by up to 40%, providing a substantial return on investment.

API594 Cast Steel Swing Check valve

Maintaining your check valves regularly is one of the simplest and most effective ways to prevent costly repairs, improve operational efficiency, and enhance safety in your system. Follow these straightforward guidelines to ensure that your check valves perform optimally, extend their service life, and minimize disruptions in your system.

If you're looking for high-quality Gost check valves for your fluid systems, we can help you find the right valve for your specific needs. China · Yuanda Valve Group Co., LTD. is here to assist you in selecting the best check valves for your applications and ensuring that your systems operate smoothly and safely.

Read More:

Where Is the Check Valve Installed?

What Are the Commonly Used Check Valves?

Maintenance of Pneumatic Ball Valves