Home >> Products >> DIN Standard >> Cast Iron >> Globe Valve >> DIN Cast Iron Bellows Seal Globe Valve - Yuanda valve

Technical Requirement:

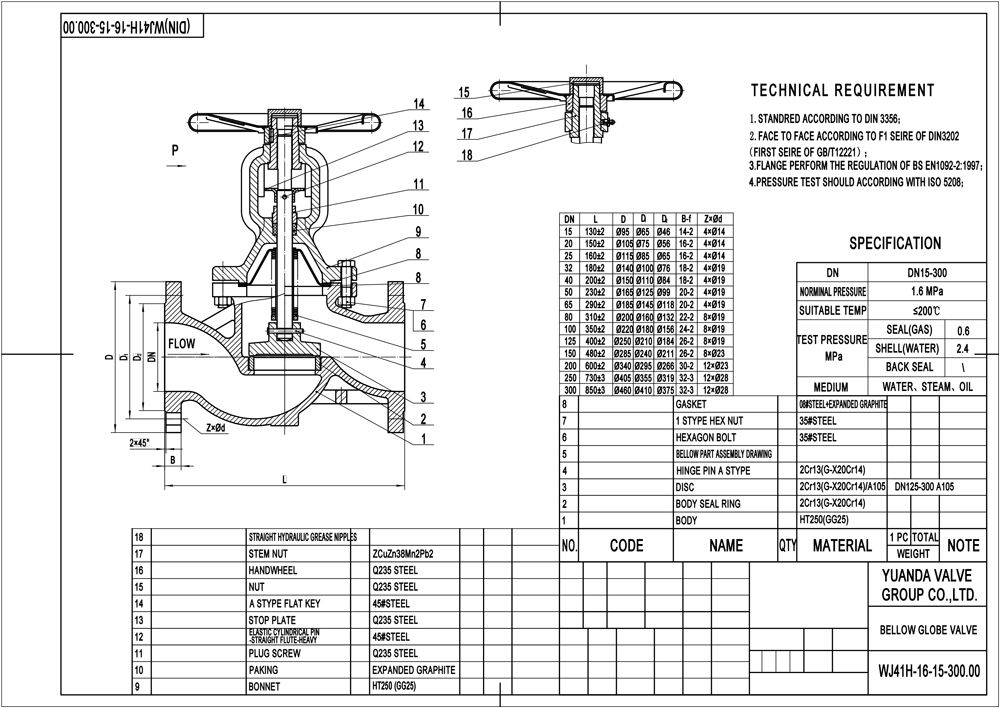

1. Design and Manufacture: DIN 3356;

2. Face to Face: F1 SEIRE OF DIN3202

3. Flange End: BS EN1092-2:1997;

4 Test: ISO 5208;

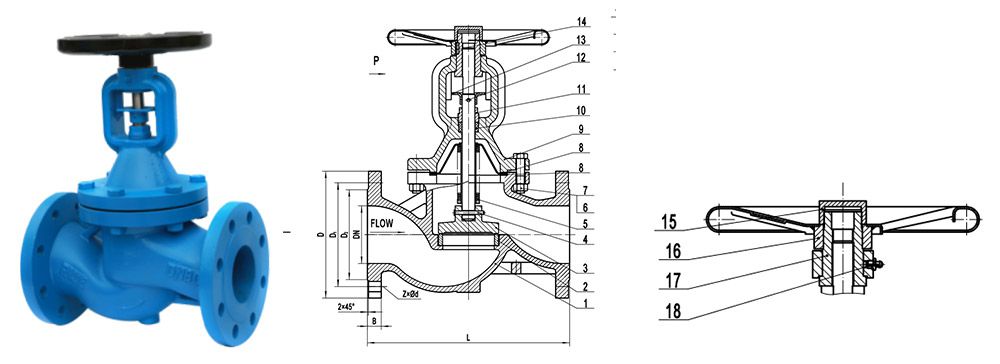

Product Details

| Parts Name | Materials |

| Body、Bonnet | GG25/GGG50 |

| Disc | GG25/GGG50 |

| Stem | 2CR13 |

| Seat Ring/Bellow | SS304 |

The bellows globe valve is a specially designed valve for use in industries that handle hazardous media. Even a minor leak can be fatal. With the exponential growth of emerging industries such as the chemical and nuclear industries, more and more flammable, hazardous, highly toxic and poisonous media are flowing through pipelines. This leads to a high risk of leaks, explosions and health hazards. Therefore, valves used in such pipelines and systems have certain stringent leakage and sealing requirements.

The requirement for a completely different approach to the required sealing and redundancy has led to the development of bellows seal globe valves.

Our product line includes a variety of bellow seal valve solutions, such as the bellow seal globe valve and bellows sealed valves, designed to provide superior sealing and prevent leakage. For specialized applications, we offer the bellow seal ball valve and the explosion-proof bellow sealed globe valve, ensuring safe and reliable operation in hazardous environments. Our high-quality bellows valve technology is paired with durable globe valve parts to deliver optimal performance and long service life in critical systems.

1. Bellows globe valves, also known as bellows seal globe valves, form a metal barrier between the fluid medium and the atmosphere through automatic welding, using a double seal design, to ensure that the product reaches zero leakage, especially for toxic and harmful and other dangerous gases.

2. The Inside of the stainless steel bellows is welded to the stem to prevent process fluids from corroding the stem, and through automatic hobbing welding, a metal barrier is formed between the fluid medium and the atmosphere to ensure that the stem is designed for zero leakage.

Bellows Sealed Globe Valves designed for various applications with inflammable, explosive, volatile, toxic or aggressive characteristics to provide the highest fugitive emission protection.

Full safety sealing system with multiple-walled bellows, gland packing, metal back seat, and position indicator.

Two-part rising stem design separates the upper and lower stem from each other which prevents bellows from torsion.

Long cycle life bellows (10,000 cycles): Designed and qualification tested for high pressure/high temperature applications.

For various media with inflammable, explosive, volatile, toxic or aggressive characteristics, whose emission into the atmosphere must be prevented.

For applications where valve leakage or leaks are unacceptable, such as heat transfer oils, toxic fluids, steam and conditioning media.

Our bellows technology prevents corrosive or hazardous atmospheric conditions from entering the process.

What are the benefits of using bellows seal globe valves?

The primary function of bellows seal globe valves is to prevent potentially harmful or toxic unorganized emissions that could negatively impact unprotected humans and the surrounding environment. In addition to reducing the risk to employees or the environment, these valves reduce material losses during operation, thereby reducing total material costs and increasing production.

How do I choose bellows seal globe valves?

There are several factors to keep in mind when selecting bellows seal globe valves for your system. Some key design considerations are:

The material selected for bellows seal globe valves should be compatible with the operating conditions of the system, including fluid media, temperature and pressure.

Pressure levels. bellows seal globe valves should be rated to handle the expected pressure and temperature range of the fluid system.

Design qualification. Ensure that bellows seal globe valves meet industry standards such as EPRI, MSS, API, or ISO.

bellows seal globe valves should be sized to fit the design of the system.

How can I prevent bellows seal globe valves from failing?

bellows seal globe valves are designed for reliable operation. Although rare, they do break down. Often, the root cause of failure is not the quality of the valve or bellows, but rather improper selection, installation or operation. Some guidelines for avoiding valve failure include:

Monitor for excessive back pressure or high inlet pressure changes.

Select the proper size valve and bellows.

Operate within the design pressure, temperature, and stem travel range.

Prevent cavitation, flashover, and other abnormal and destructive flow conditions.

In recent years, Yuanda has witnessed a rising awareness in engineering field and international field, established long-term and stable cooperation relationship with famous enterprises and several transnational groups in fields such as petroleum, petrochemical, water conservancy and steel and made its vision a reality. Yuanda attaches importance to after-sales services, continues to improve after-sales service mechanism: it's Yuanda's service philosophy to stay customer-oriented and provide quick-response and quality services. We commit that we are always ready to help no matter where you are.

The bellows valve is a specially designed valve for industries where even minor leaks can be fatal in handling hazardous media. With the exponential growth of emerging industries such as the chemical and nuclear industries, more and more flammable, hazardous, highly toxic and poisonous media are flowing through pipelines. This leads to a high risk of leaks, explosions and health hazards. Therefore, valves used in such pipelines and systems have certain stringent leakage and sealing requirements.

The requirement for a completely different approach to the required sealing and redundancy has led to the development of bellows-sealed globe valves.

The metal bellows is the main feature of the bellows ball seal valve. There are two types of bellows :

Formed bellows

Formed bellows is made by rolling a flat sheet into a tube and fusion welding it longitudinally. Thereafter, the tube is mechanically formed into a bellows with round and widely spaced folds.

Welded vane bellows

In this type, thin metal plates in the form of gaskets are welded together. Welding is performed on the inside and outside of the gasket-like plates. The welded vane bellows is folded more times per unit length.

For both formed and welded vane bellows, the amount of movement per fold is the same. Thus, for the same stroke rate, the mechanically formed bellows is two to three times longer than its welded equivalent vane.

The lower end is welded to the stem assembly by automatic seam welding, while the upper end is welded to the connection plate by automatic seam welding, creating a metal shield between the fluid medium and the environment, ensuring zero stem leakage.

The sealing surfaces of the valve disc and valve structure are precision ground so that once the installation is complete, it can be confirmed that it has passed the pressure test 100 % and the possibility of any type of leakage is eliminated. As a secondary seal, the stuffing box is always secured to the bellows for increased durability and protection. The metal bellows of the high pressure valve has a multi-layer construction and is hydroformed to guarantee an open/close life of 10,000 cycles at maximum pressure.

Bellows seal globe valves are compact, control valves that utilize a bellows to seal the stem components. The bellows valve has an internal bellows with the lower end of the stainless steel bellows welded to the stem to prevent system fluid from corroding the stem. The other end is located between the valve body and bonnet to create a permanent seal. This double seal construction eliminates leakage, meaning that even if the bellows ruptures, the stem packing prevents further leakage. The bellows is welded to the stem to ensure consistent efficiency and to prevent stem vibration caused by spool movement.

1. The most outstanding advantage of any bellows seal globe valves is the double seal design (bellows + packing). Therefore, even if the bellows fails, the stem packing prevents any kind of leakage and meets international sealing standards.

2. Minimize the loss of media fluid to ensure safety and environmental protection. This will ultimately improve the safety of the plant where the bellows valve is installed.

3. It can be used as an energy saver as it helps to reduce the energy loss due to leakage.

4. Since leakage is minimized, this avoids frequent maintenance of the valve. Therefore, it leads to a longer valve life.

5. Due to longer service life, operation and maintenance costs are greatly reduced.

6. The robust bellows seal design ensures zero leakage from the valve stem, thus providing a maintenance-free condition.

7. Due to the installation of bellows valves, the discharge of flammable, toxic and hazardous chemicals can be minimized, thus improving the safety of personnel.

When valves with gland packing are used, such as gate valves or ball valves in hot oil delivery systems (where the permeability of hot oil is about 50 times that of steam), there is a high chance of hot oil spillage, which may result in damage to equipment and property. In this case, the bellows valve ensures absolutely zero leakage due to its construction.

In ordinary valves, the shape of graphite packing does not provide 100% effective sealing, which is the main reason for frequent leaks in packed valves. Since ordinary packing is made of graphite, if the graphite is not pure enough, its oil resistance will be reduced. When the hot oil being transported is immersed in the graphite packing, certain graphite impurities are separated out and flow with it.

When using a ball valve in a hot oil system, if the internal PTFE is not resistant to high temperatures, it will quickly break down and cause the valve to leak.

The internal parts of the bellows valve are made of stainless steel and can withstand temperatures up to 425°c. Considering the lifetime of bellows seal globe valves, the average bellows valve has a service life of more than three years. Therefore, in order to maintain output reliability and reduce direct operating costs, bellows seal globe valves are preferred over normal seal valves in systems that convey hot oil.

1. Select the inside diameter of the bellows according to the diameter of the valve stem. The inside diameter of bellows should be larger than 115mm stem diameter.

2. The outer diameter of the bellows is selected according to the inner diameter of the bellows. The outer diameter and inner diameter are expressed by the ratio of outer diameter to inner diameter. Usually, the ratio of outer diameter to inner diameter is 113 to 115.

3. The wall thickness, number of layers, number of corrugations and length of the bellows must meet the requirements of pressure resistance, stroke and cycle life of the bellows. Under normal circumstances, the higher the pressure, the greater the thickness of the bellows is required. In order to increase the displacement or reduce the stiffness of the bellows and increase the life, the thickness of a single layer can be reduced and the number of layers of bellows can be increased.

4. For handling higher pressures, multiple bellows designs are recommended. The pressure that the bellows can withstand can be increased by using 2 or 3 metal walls, as in the multiple design of bellows. Compared to a single layer of bellows of the same thickness, the pressure rating of a double layer bellows can be increased by 80% to 100%. Alternatively, the stroke length is shortened if a single-layer bellows with a thickness equal to the pressure rating of the double-layer bellows is used. Thus, we gain a clear advantage of multi-layer design compared to single-layer thick bellows.

5. In order to prevent the bellows from deformation, the designed guiding structure must be strictly followed.

6. To prevent wear and premature failure, local contact between the valve stem or bellows must be avoided.

7. The design should prevent the bellows from twisting and torsional deformation.

8. The valve design should be limited by the extension travel and compression of the expansion tube. This is to prevent the bellows from shifting and to withstand compression and tension beyond the specified cycle life test. Under normal conditions, the bellows should not travel more than 25% of its free length. Failure to do this will affect the cycle life of the bellows, especially for bellows valves in high temperature and high pressure environments.

9. The bellows uses the same pressure and temperature rating as the bellows-sealed globe valve. Bellows must be able to withstand the nominal pressure of the main valve at 38 ℃ and 115 times the nominal pressure at 38 ℃ pressure test. During the pressure test, the welds should not crack or leak and the bellows should not be twisted.

10. The material of the bellows assembly should be selected within the allowable temperature range and should have good formability, weldability and compatibility with the medium.

Bellows seal globe valves eliminate the risk of process fluid leakage and are therefore ideally suited for applications where it is not possible to eliminate leakage from the valve. Therefore, these valves are preferred where hydrogen, ammonia, chlorine and other similar toxic or explosive substances are handled.

Shut-off valves for heat transfer oil, toxic, flammable, highly permeable, environmentally contaminated and radioactive fluid lines. It can be considered as a quality product for creating leak-free plants.

Just to name a few, bellows seal globe valves are widely used in petrochemical, electronics industry, various plants, vacuum industry, etc.

To avoid damage or injury to personnel or equipment, be sure to read all warnings and instructions. Unprofessional readjustment, use of foreign replacement parts or incorrect maintenance procedures may result in loss of efficiency or cause injury to personnel or damage to parts.

Use double-sealed bellows in highly corrosive chemical environments so that you can obtain two layers of sealing protection.

If you notice the odor of media in the air or a wet valve cover, it is usually because the bellows has been damaged by the media.

You can replace the bellows yourself or have the manufacturer replace it. Replace it to avoid prolonged neglect, threat to life and damage to the entire valve.

An over-tightened gland nut can cause excessive packing wear and prevent free movement of the stem.

There are many reasons why bellows seal globe valves leak. bellows seal globe valves leaks are generally divided into internal and external leaks:

1. Because the liquid medium contains solid impurities, which damage the sealing surface and cause failure.

2. Combined with the analysis of field use, the cause of stem leakage is mainly related to the valve structure, working environment and operation mode.

3. The valve stem adopts the double sealing structure of bellows and packing. The bellows is welded together with the inner liner ring and outer liner ring to form a bellows assembly, which is then welded to the stem and guide body to stop the medium from leaking through the stem. bellows seal globe valves have a stem that moves up and down by means of a flat key until the upper face of the flat key contacts the lower face of the lower packing. Since the lower packing is PTFE material, if the valve is opened too far, the flat key will be embedded in the packing and bellows seal globe valves will no longer be able to open and close and the bellows assembly will be knocked dead, causing the medium to leak along the stem.

4. According to the pipeline determination process, bellows seal valves tension and compression can lead to leakage. If the tension or compression exceeds the limit, the bellows may be damaged, resulting in a small series of hose rupture and seal failure. Therefore, it is necessary to add a limiting device for opening and closing bellows seal globe valves so that the bellows is always stretched within the design range during the valve operation.

The unique design of bellows seal globe valves and its efficiency in providing leak-proof operation makes it the most suitable valve for a variety of applications, especially where hazardous materials & system media are at high temperatures. Durability, maintenance free operation and cost effectiveness are additional advantages of bellows seal valves.